Question: When is sewing more than just needle and thread?

Answer: When you are volunteering on the Matthew Turner Sewing Team.

The Matthew Turner Sewing Team brings a wide range of sewing and maritime experience to the project. Our growing group of volunteers learn what needs to be done while also teaching others how to get the job done. We study and implement every aspect of the tall ship’s complex fabric needs.

There is a whole array of things to work on, most of which involve quite a variety of materials and considerations. Everything from lee cloths, berth curtains, mattress pads, and covers for below deck – not to mention – covered cushions on deck, covers for the large sails, and the “Independence” tender that hangs off the back of the ship. Each fabric must be sourced, tested and measured before making the first cut.

Hand-in-hand with many of these projects are lessons on how to install grommets and fittings, plus learning how to splice rope and tie knots. We found our best source of information on You Tube and from Sailrite videos. These invaluable videos, plus accessing manufacturer’s guide lines have saved us much time in researching the best way to proceed. The commercial industrial sewing machines, that were donated to the tall ship, had to be fixed and polished to get them in running order. Several machines had to be specially augmented for our varying projects. This was such an undertaking!

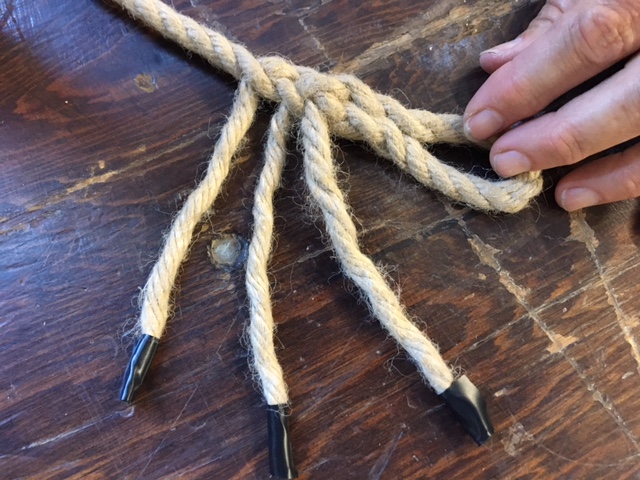

Here are some photos of the team at work (pictured to the right), including, learning how to tie an eye splice out of three strand rope for our lee cloths. We’re fortunate to have riggers on hand to teach us. We can now do this in our sleep!

Each length of rope was cut according to what we needed to reach the corner of the lee cloth to the fitting on the bunk. Then, the ends of each piece were marked with blue tape to allow six inches for splicing. A hot knife burnt the ends to prevent unraveling. The next step was to thread one end of rope through the corner grommet, then split it apart for the splicing. We also learned how to weave the ends through the rope, turning as we go, so that all three pieces were secure. Then the extra length was cut and burned with the hot knife making a smoothly woven splice.

The final product is pictured below.

Fair Winds from the ‘Sew ‘n Sews; with out motto: “We’ll keep you in stitches!”

Barbara Treadwell

Final Product

Special thanks to Marcy Pattinson for supporting our volunteers!